Get to know our solutions

SGA is a fabless manufacturer of analog and mixed-signal integrated circuits. Components from SGA are custom designed for their specific applications.

– This is what we call Specific Components™.

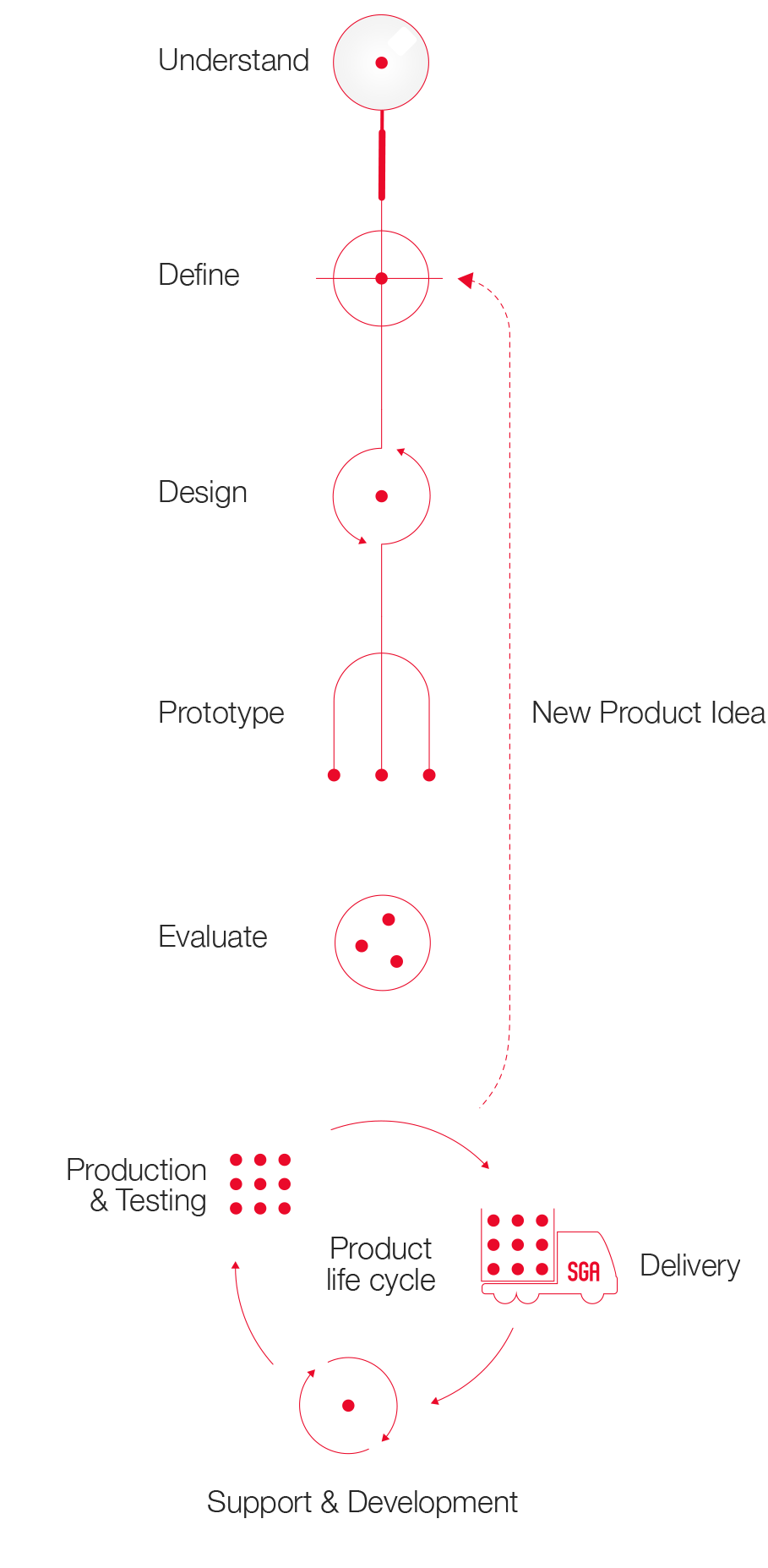

The SGA way

SGA’s development methodology means working closely with our customers during the entire product lifecycle. It has been developed over many years and is based upon the realization that the key to delivering successful products is an in-depth understanding of each customer’s unique requirements, followed by the design of components for their specific applications. We keep production running and are always looking forward to designing and producing the next generations of components.

Understand

We always take a great interest in getting to know the functionality and requirements on a system level. This is needed to offer the perfect balance of the ASIC’s functionality and the product’s performance.

Define

In close cooperation with the customer a detailed specification of the component is defined the key to a successful design.

Design

Our experienced design team will develop the ASIC design while keeping the customer continuously in the loop to maintain a close dialog with productive feedback.

Prototype

Prototypes are manufactured using the same process as the full-scale production to ensure functionality behavior comparable to the final product.

Evaluate

Component prototypes are evaluated by the customer and SGA in unison to establish perfect operation under all conditions.

Production & Testing

SGA uses subcontractors from all around the globe, but all final testing

is done in-house. This ensures that unexpected variations will be

detected – and action taken – immediately.

New Product Idea

The more we learn about our customer’s business, the more we can discover and develop components that help and benefit their business. We are always ready to discuss new components for the next generation of customer applications.

Delivery

All components are delivered from SGA´s facilities directly to the customer.

Support & Development

We take pride in being a reliable supplier during the entire life cycle of the component, ensuring customer satisfaction by listening and addressing specific needs and concerns as soon as they arise.

Production & Testing

SGA uses subcontractors from all around the globe, but all final testing is done in-house. This ensures unexpected variations will be detected – and action applied – immediately.

Delivery

All components are delivered from SGA´s facilities directly to the customer.

Support & Development

We take pride in being a reliable supplier during the entire life cycle of the component. Ensuring customer satisfaction by listening and addressing specific needs and concerns as soon as they arise.

New Product Idea

The more we learn about our customers’ business, the more we can discover and develop components that help and benefit their business. We are always ready to discuss new components for the next generation of customer applications.

Curious about our application areas?

Why ASIC?

Customized mixed-signal ASICs have unique benefits over standard components. For example, achieving extremely low power consumption, reducing noise, achieving higher gain, and operating at higher or lower voltages all this while reducing the overall footprint.

While simplifying the design, an ASIC can also add additional custom features that might previously have been tedious and difficult to implement using a traditional standard component structure, gaining even more performance. In addition to performance benefits, introducing an ASIC to your system can help reduce production costs and secure long-term availability. Furthermore, an ASIC can help protect your IP by making your application much more difficult to copy or reverse engineer thanks to the nature of its custom design.

Choosing SGA to help bring your vision to life brings our team’s wealth of experience to the table. We want to be a part of your design process to help you maximize the performance of the ASIC and enable you to differentiate your product in the market.

At SGA we handle the production and testing to help manage the supply chain for you after the design is finalized. The road together does not end after delivery, SGA will continue to support you through your products’ life cycle delivering more components and helping you to improve any future iterations you may want to create.

In the end, there are several reasons why an ASIC is a smart choice. Aside from the multiple performance benefits, an ASIC can reduce the size of the electronics in the application and might even be the only way to fit the electronics into a given form factor. After the initial cost of development, the use of an ASIC will generally cut costs for production. During the life cycle of the product, the cost savings and performance gains will undoubtedly leave you happy with the decision to use an ASIC.

Specific requirements

Special requirements that can’t be met with standard components can be impractical or impossible to implement with a discrete solution. Such requirements can normally be met with an ASIC solution. Lower current consumption, lower noise, higher gain, higher temperature, higher supply voltage/lower supply voltage; the requirements are many times difficult to combine but with an ASIC we can optimize the balance between these requirements according to your specific needs.

BGA, QFN, or Bare die? Together with you, we select the best possible package for the application. Choice of the production process may be difficult and have a significant impact on the project. We’re experienced with a variety of processes and know the value of finding the right one. As a specific example, we’re a great experience from SOI processes offering 200V transistors, very low leakage current as well as operating temperatures up to 225°C. SGA can also offer Hi-Rel production flows and customized screening and qualification pro-grams like MIL-STD-883 or similar JEDEC-standards.

Drop-in-replacement

If you’re facing any EOL or LTB concerns, SGA can help.

We can design a drop-in replacement for existing parts that have turned obsolete. Other parts of the system can therefore be left unchanged. Your re-design efforts and the need for re-qualification will be minimized.

After the design of the drop-in replacement ASIC, we also handle production, testing, and the supply chain, giving you access to a secure source of components.

Life cycle

Selecting a partner that designs your ASIC, in combination with managing the production, ensures that you will get long-term product support. We’ll be there to support you during your product’s entire life cycle and want to be a part of your next-generation products.

Outsource development and supply

Companies most often want to concentrate efforts where they are most needed. Creating and maintaining an ASIC design in-house and subsequently managing the supply chain may not be the desired way to spend those resources. SGA can offload your team and help with the design and production of ASIC solutions that compliments your product thanks to our full turnkey offering.